Product Introduction

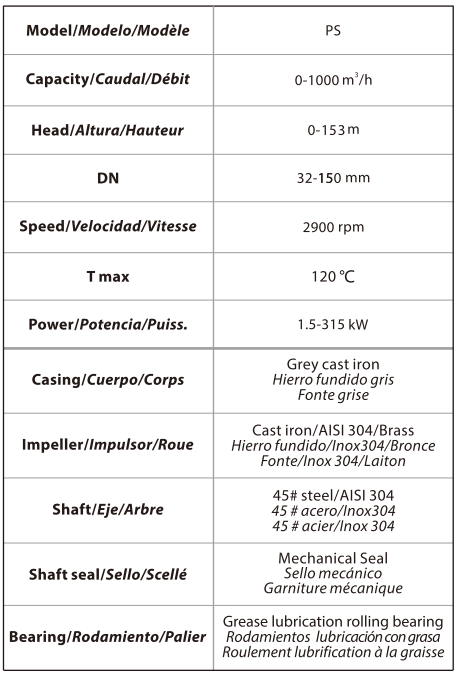

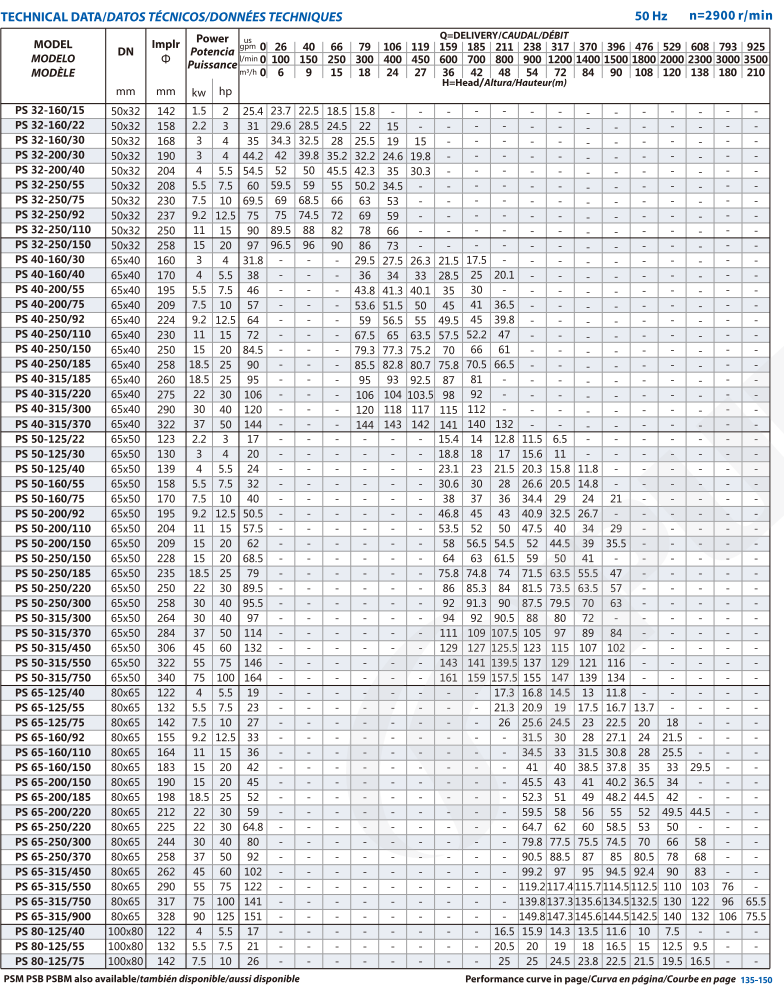

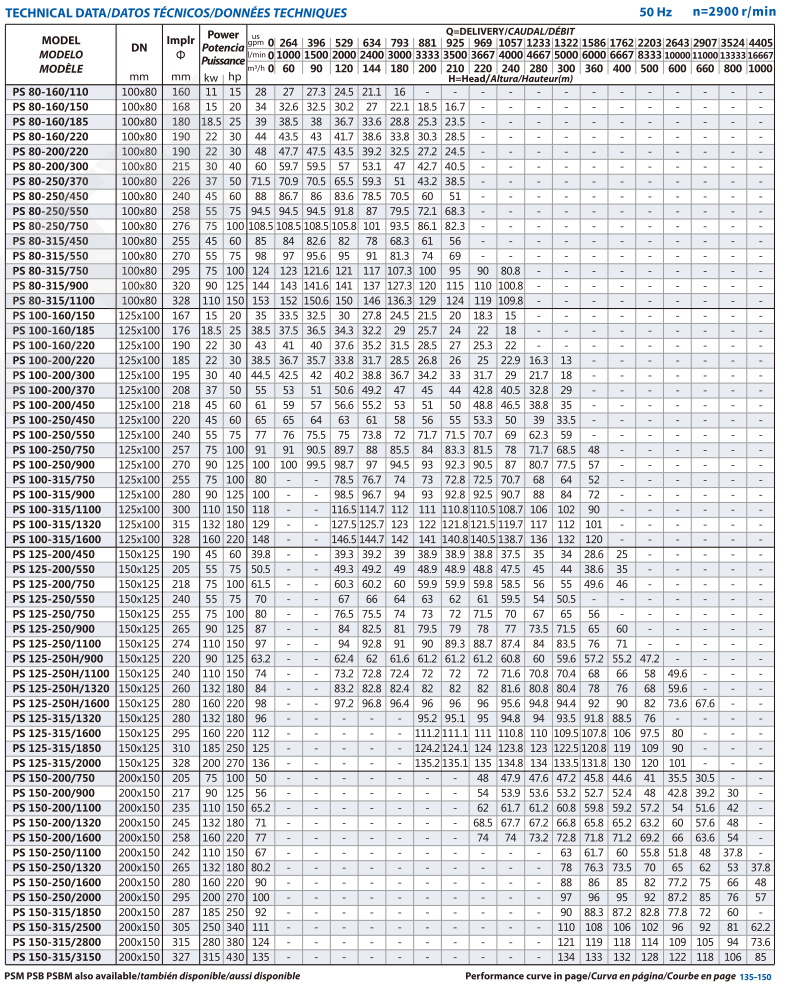

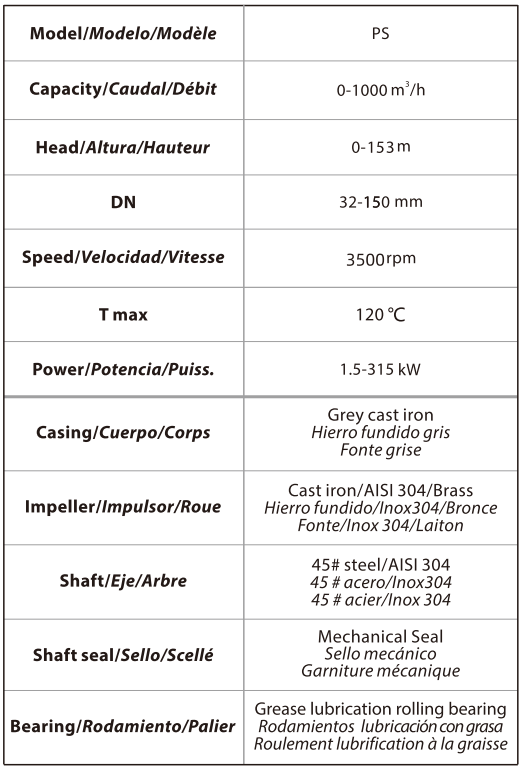

The Purity PSM end suction centrifugal pumps are engineered to deliver stable, efficient, and reliable performance across a wide range of operating conditions. A key design feature is its adequately sized inlet, which ensures sufficient water supply during operation. By reducing vortex formation at the suction port, the end-suction centrifugal pump lowers the required Net Positive Suction Head and effectively minimizes the risk of cavitation. This results in smoother operation with reduced vibration and noise, ensuring long-term performance stability even in systems with fluctuating flow demands.

To enhance hydraulic efficiency, the Purity PSM end-suction centrifugal pump is developed using advanced hydraulic simulation technology. This optimized hydraulic design provides a smooth performance curve, minimizes internal flow losses, and improves overall pumping efficiency. As a result, the end-suction centrifugal pump performs exceptionally well in applications such as water supply, industrial circulation,irrigation, and general fluid transfer, offering versatility and dependable operation.

Durability and ease of maintenance are central to the end-suction centrifugal pump’s construction. The pump casing is coated with a high-quality corrosion-resistant layer that protects the surface from rust and environmental wear, significantly extending the pump’s service life. Premium NSK bearings are used to ensure precise rotation, low friction, and long-lasting mechanical stability. Additionally, Purity PSM end suction centrifugal pumps are equipped with a wear-resistant mechanical seal that delivers reliable sealing performance, effectively reducing leakage risks and maintenance frequency.

Purity is one of end suction centrifugal pump manufacturers in China,and has been supply horizontal end suction centrifugal pump to all over the world.