Product Introduction

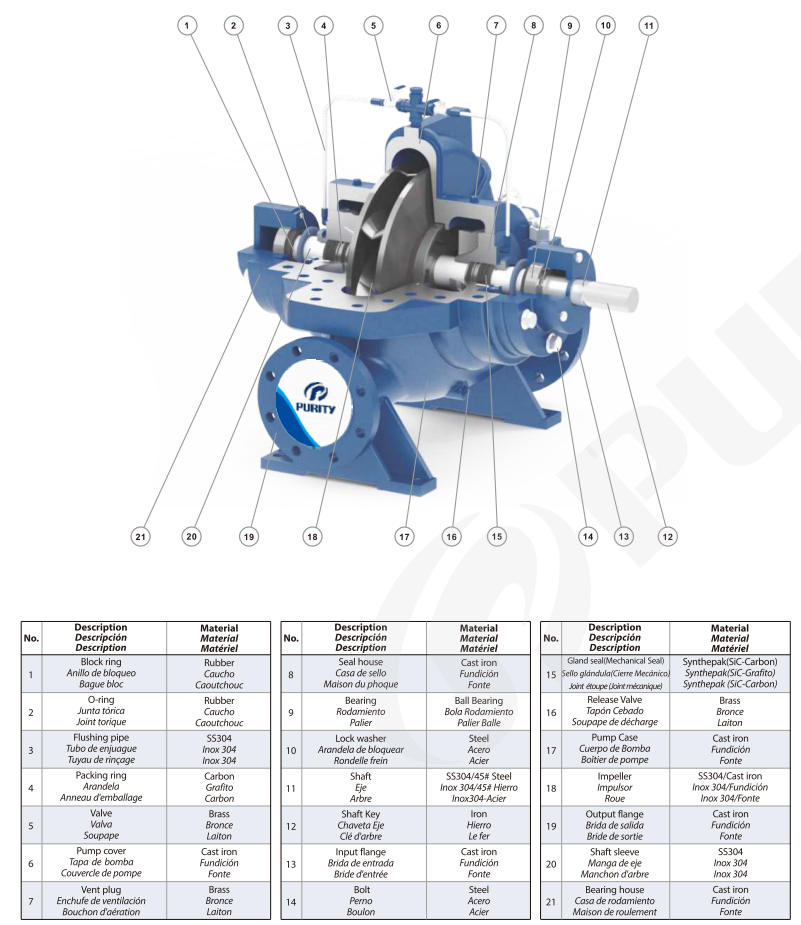

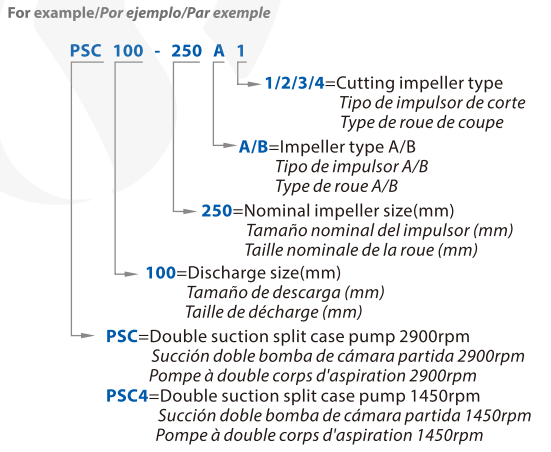

Its axially split volute casing design allows easy access to internal components without disconnecting the pipework, greatly simplifying inspection and maintenance. Purity PSC split case centrifugal pump features a double suction radial impeller, which ensures balanced hydraulic forces, reduced axial load, and smooth, vibration-free operation. To meet different application needs, users can select between AISI 304 stainless steel or HT250 cast iron materials, offering flexibility for both corrosive and standard water supply conditions.

To enhance PSC axially split centrifugal pump's long-term durability, the HT250 pump casing is coated with a corrosion-resistant protective layer. This ensures reliable operation even in harsh environments such as industrial circulation systems, municipal water networks, cooling systems, and fire protection installations. The robust casing structure resists wear, corrosion, and pressure fluctuations, guaranteeing extended service life.

Purity PSC centrifugal pump split case is equipped with grease-lubricated rolling bearings, designed with long-lasting seals that prevent liquid ingress and protect critical components from damage. This bearing system not only minimizes maintenance needs but also reduces repair costs by extending the operational life of the split case centrifugal pump’s internal parts.

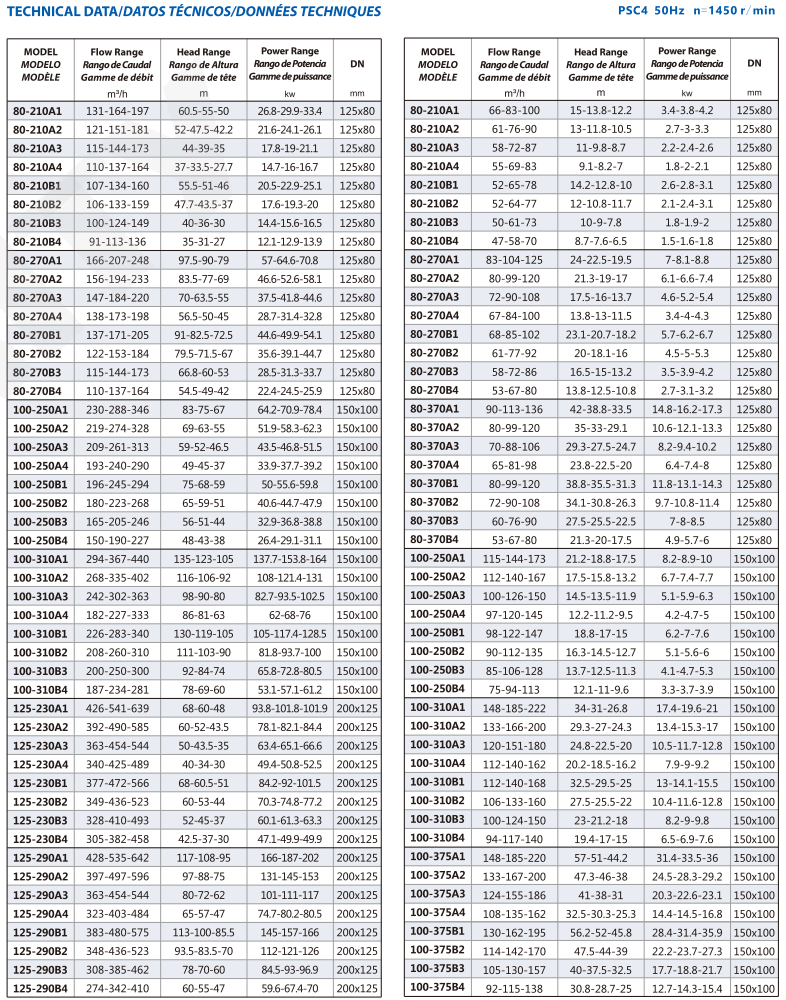

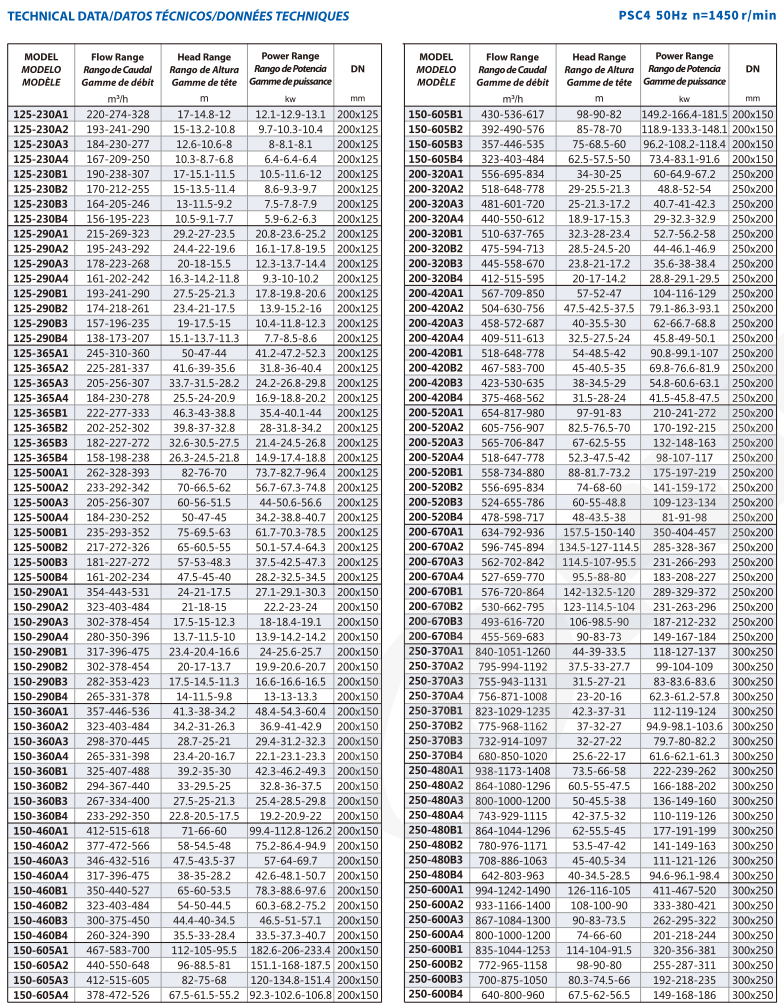

With compatibility for both electric motors and diesel engines, the Purity PSC axially split centrifugal pumps offer broad installation flexibility. It can be configured for various flow rates and pressure requirements, making it suitable for water plants, industrial processes, HVAC systems, irrigation, and fire-fighting applications.