Sewage pumps are essential mechanical devices designed to transport wastewater containing solid particles (up to 2 inches in diameter) from residential or commercial buildings to municipal sewer systems or septic tanks. As a leading sewage pump company with 15 years of expertise, Purity understands these systems are particularly crucial for basements and lowlying areas where gravity drainage is ineffective.

Modern submersible sewage pumps operate automatically, preventing dangerous sewage backups that could lead to:

1. Centrifugal Pump Principle

All sewage treatment plant pumps utilize centrifugal force:

- An electric motor rotates an impeller at high speed

- This creates pressure differentials that push wastewater

- Solid particles pass through specially designed channels without clogging

2. Automatic Operation System

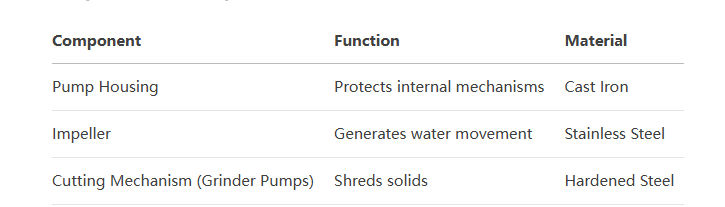

3. Specialized Components

1. Standard Sewage Ejector Pumps

Handles raw sewage with solids

Ideal for sewage pumps for basements

Purity models feature epoxysealed cables for durability

2. Effluent Pumps

For pretreated wastewater (lower solid content)

Common in septic system discharge

3. Grinder Pumps

Equipped with rotating blades to macerate solids

Essential for highsolid applications

Reduces maintenance frequency by 40% vs standard models

As an ISO 9001 & CE certified manufacturer, Purity WQ Submersible sewage pump offer:

✅ Extended Product Lifespan

Unique epoxy cable sealing technology

Mechanical seal pressure plate design

✅ Comprehensive Model Range

Flow rates from 6 to 1500 m3/h

Figure | Purity submersible sewage pump WQ

1. Quarterly Inspections

Clean the sump basin of debris

Test float switch operation

Verify GFCI protection

2. Troubleshooting Signs

⚠️ Unusual pump noises

⚠️ Slow drainage speed

⚠️ Persistent sewage odors

Whether you need submersible sewage pumps for residential basements or heavyduty sewage treatment plant pumps, understanding these systems prevents costly failures. Key selection factors include:

Purity's engineered solutions combine Italy designs with robust Chinese manufacturing. Contact us today to discuss your project requirements or global distribution opportunities.