Centrifugal pumps play a crucial role in many industrial systems, facilitating the efficient movement of liquids such as water, chemicals, and various other fluids. When selecting a centrifugal pump for a particular application, one of the primary decisions is whether to choose a split case centrifugal pump or an inline centrifugal pump. Each type of pump has its advantages depending on the specific needs of the system, such as space availability, flow rates, and pressure requirements. In this article, we will explore the differences between these two popular types of centrifugal pumps to help you make an informed choice for your application.

A split case centrifugal pump features a casing that is split into two parts, typically along a horizontal plane. This design allows for easy access to internal components, making it simpler to maintain and service the pump. The impeller in these pumps is positioned between two bearings, ensuring a balanced operation that reduces vibration and increases the smooth flow of fluids.

Picture| Purity PSCM Split-Case Pump

Design and Function:Split case pumps are commonly used for high-flow, high-pressure applications. Their robust design and dual-suction impeller provide efficient fluid movement, especially in large-scale systems.

Applications: They are ideal for use in municipal water supply systems, industrial cooling systems, and agricultural irrigation systems. These pumps can efficiently handle large volumes of liquid, making them essential in industries that require continuous, high-volume fluid transfer.

Installation and Maintenance: While the installation of a split case pump is more complex due to its size and required base preparation, its horizontal design allows for easier maintenance. The pump can be opened horizontally for quick access to internal components.

An inline centrifugal pump is designed with a compact structure where the pump casing is mounted directly inline with the piping system. The impeller is typically positioned along the same axis as the suction and discharge nozzles. This design significantly reduces the space required for installation, making inline pumps an excellent choice for installations where space is limited.

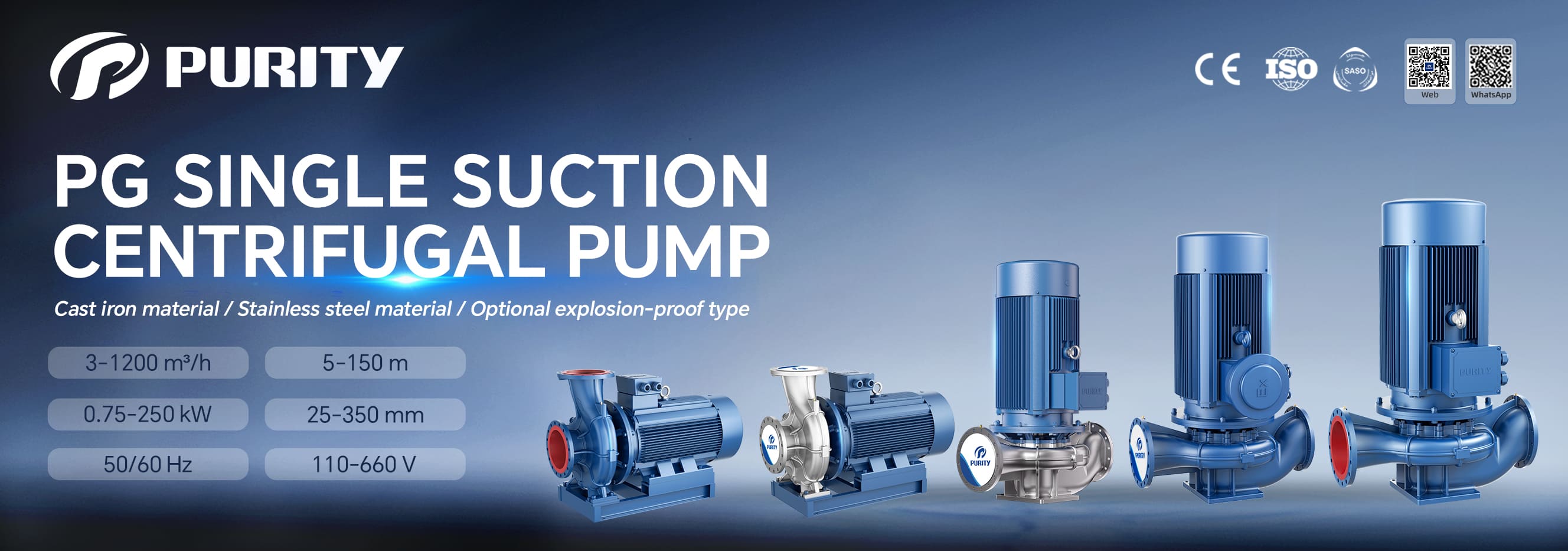

Picture|PG Series Centrifugal Water Pumps

Design and Function: Inline centrifugal pumps are characterized by their streamlined design. The motor is typically mounted directly above the pump, and the suction and discharge ports align in a straight line, minimizing additional space requirements. This makes them particularly suited for applications where space-saving is a priority.

Applications: These pumps are commonly used in HVAC systems, water circulation in high-rise buildings, fire-fighting systems, and boiler feed units. Inline centrifugal pumps are especially useful in environments where the available space is constrained.

Installation and Maintenance: The installation of an inline centrifugal pump is relatively simpler, as it can be mounted directly onto the pipeline. This compact design also makes maintenance easier in many cases, though servicing can be more challenging if the pump is in a very tight or difficult-to-reach location.

Split Case Pumps: These pumps have a horizontal shaft and are typically mounted horizontally. The casing is split along the horizontal plane, allowing for easy maintenance and servicing.

Inline Pumps: Inline centrifugal pumps feature a vertical or inline shaft design, with the pump casing mounted directly in line with the piping system. This results in a more compact design that takes up less space.

Split Case Pumps: Best suited for large-scale operations that require high flow rates and higher pressure, such as municipal water systems, large industrial cooling plants, and agricultural irrigation.

Inline Pumps: Typically used in applications where space is limited, such as HVAC systems, fire protection systems, and water circulation in high-rise buildings. They are ideal for moderate flow rates and pressures.

Split Case Pumps: Due to their larger size and horizontal mounting, split case pumps require more installation space and a more complex base setup.

Inline Pumps: Their compact design allows them to be installed in areas with limited space, making them suitable for installations in small or confined spaces.

Split Case Pumps: These pumps are designed for higher flow rates and can handle larger volumes of liquid. They are typically more efficient in high-demand applications where reliability and performance are critical.

Inline Pumps: Inline centrifugal pumps are efficient for medium flow rates and pressures, and their space-saving design makes them a popular choice in systems with specific space constraints.

Split Case Pumps: Maintenance is easier due to the ability to open the pump horizontally. Regular checks and part replacements are more straightforward, making split case pumps ideal for systems with high maintenance demands.

Inline Pumps: While installation is simple, maintenance may be more challenging due to the pump's compact design, especially if the system is in a hard-to-reach location.

When choosing between a split case centrifugal pump and an inline centrifugal pump, the key factors to consider are the space available for installation, the required flow rates and pressures, and the ease of maintenance. If your application demands high flow rates and high pressure, and you have sufficient space for installation, a split case pump may be the best choice. However, if space is a constraint and you need a more compact solution, an inline centrifugal pump is likely the better option.

At Purity Pumps, we offer a wide range of centrifugal pumps, including horizontal split case pumps, inline centrifugal pumps, and self-priming pumps. Our PSCM split case pumps are designed with a split casing for easy maintenance and reliable operation. Our PGL vertical inline pumps offer a compact, efficient solution for space-constrained environments. With over 15 years of experience and a global presence in over 130 countries, we are committed to providing high-quality pumps that meet the needs of diverse industries.

In conclusion, understanding the differences between split case centrifugal pumps and inline centrifugal pumps is essential for optimizing your system’s performance. Whether you prioritize high flow rates, compact design, or ease of maintenance, selecting the right pump will significantly enhance your system’s efficiency and reliability.